Our A-1200 pressure sensors have been designed for intuitive and flexible programming via an IO-Link. This state-of-the-art pressure sensor is an ideal solution for any intelligent applications whether you’re looking for simple pressure monitoring or electronic PNP/NPN switching for process control environments.

Our A-1200 pressure sensors have been designed for intuitive and flexible programming via an IO-Link. This state-of-the-art pressure sensor is an ideal solution for any intelligent applications whether you’re looking for simple pressure monitoring or electronic PNP/NPN switching for process control environments.

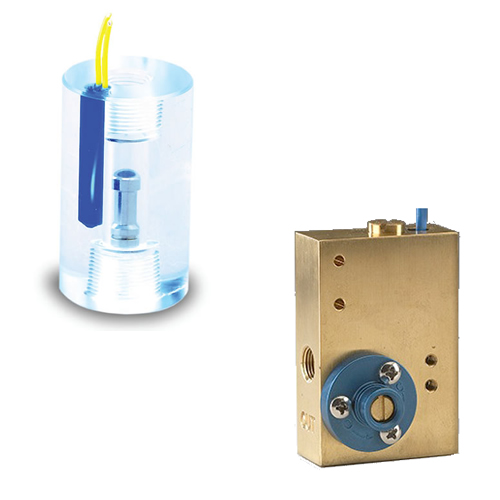

IO Link with PNP or NPN Switching Output

These pressure sensors ensure precise measurement results over a long-term period thanks to their integrated smart diagnostics functions that monitor the instrument status. Additionally, this IO Link sensor can be configured remotely via the digital signal and conveniently adjusted at any time this is required.