Reliable pressure control is essential to safe and efficient operations in many industrial plants. Pressure regulators that are specified properly can make the difference between good and poor pressure control — often critical to ensuring system safety, product quality, plant throughput and efficiency.

Our standard pressure reducers and back pressure regulators are designed to fulfil a vast range of needs in instrumentation sample systems and other high-quality applications. We have optimised our stock profiles to ensure that our pressure regulators are in stock and always readily available off-the-shelf in a variety of customised configurations.

To keep your system safe, optimised and operating as intended, selecting and installing suitable pressure regulators is important. Explore our extensive catalogue or reach out to our knowledgeable technical support team for personalised support in determining the right pressure-regulating solutions for your plant and processes.

When selecting and installing pressure regulators, it is crucial that they are sized appropriately for the system. This can help reduce system inefficiencies, prevent safety incidents such as losses of containment and improve operating costs. Specifying pressure regulators involves a number of considerations, which depending on your system, can include:

With our industry-leading expertise, our team can help businesses specify suitable pressure regulators to meet their exact system requirements. From general industrial processes to critical high-pressure control systems, our experts are experienced in helping clients understand the configurations available and select the best solutions for their process.

We offer a diverse range of pressure regulators, including approximately fifty GO products that can be configured to cater to a range of applications, media and environments.

For a summary overview of how some of our core pressure-reducing and back-pressure models compare on technical specifications, please see the below quick reference chart:

| Model | Description |

Max. Inlet |

Control Pressures | Seat/Actuator Materials |

Flow Coefficients (Cv) | Port Types | Type/Applications |

|---|---|---|---|---|---|---|---|

| PR1/PR2 |

Standard Pressure Reducing |

3,600 PSIG up to 6,000 PSIG | 0 – 10 PSIG up to 0 – 750 PSIG |

Tefzel, CF PTFE, Polyimide, PCTFE, High Density PTFE or PEEK | 0.06, 0.20, 0.025 or 0.50 | ¼” FNPT, 3/8” FNPT or Tube Stubs | Diaphragm Actuated for Gas and Liquid Control |

| PR7 |

High Flow Pressure |

300 PSIG up to 3,600 PSIG | 0 – 1 PSIG up to 0 – 500 PSIG | Viton, PTFE, Kalrez or PEEK | 1.10 | ¼” FNPT, 3/8” FNPT, ½” FNPT or Tri-Clover | Diaphragm Actuated for Gas and Liquid Control |

| PR7LF |

High Sensitivity Pressure |

300 PSIG up to 3,600 PSIG | 0 – 6 PSIG up to 0 – 250 PSIG | Tefzel, Viton, PCTFE, High Density PTFE or Kalrez | 0.06, 0.20, 0.025 or 0.50 | ¼” FNPT, 3/8” FNPT, ½” FNPT or Tri-Clover | Diaphragm Actuated for Gas and Liquid Control |

| MR1 |

Ultra Miniature Pressure |

3,600 PSIG up to 6,000 PSIG | 0 – 10 PSIG up to 0 – 500 PSIG | Tefzel, PCTFE or PEEK | 0.06 or 0.025 | 1/8” FNPT, 1/16” FNPT or Surface Mount | Diaphragm Actuated for Gas and Liquid Control |

| PR50 |

High Pressure Reducing |

3,600 PSIG up to 6,000 PSIG | 0 – 500 PSIG up to 0 – 2,000 PSIG | Tefzel, Polyimide, PCTFE, High Density PTFE or PEEK | 0.06, 0.20 or 0.025 | ¼” FNPT, 3/8” FNPT or Tube Stubs | Diaphragm Actuated for Gas and Liquid Control |

| PR56/PR57 |

Ultra High Pressure |

10,000 PSIG | 0 – 250 PSIG up to 0 – 10,000 PSIG | Polyimide or PEEK | 0.05 or 0.20 | ¼” FNPT, 3/8” FNPT or Tube Stubs | Piston Actuated for Gas and Liquid Control |

| PR59 |

High Pressure/ |

1,000 PSIG up to 4,000 PSIG | 0 – 250 PSIG up to 0 – 4,000 PSIG | PCTFE or Teflon | 1.20 | ½” FNPT or ¾” FNPT | Piston Actuated for Gas and Liquid Control |

| CYL20 |

Dual Stage Cylinder |

3,600 PSIG up to 6,000 PSIG | 0 – 10 PSIG up to 0 – 500 PSIG | Tefzel, PCTFE, High Density PTFE or PEEK | 0.06, 0.20, 0.025 or 0.50 | ¼” FNPT, 3/8” FNPT or Tube Stubs | Dual Diaphragm Actuated for Gas and Liquid Control |

| BP3 |

Standard Back Pressure |

3,600 PSIG | 0 – 250 PSIG up to 0 – 1,000 PSIG | Viton, Kalrez, High Density PTFE, Polyimide or PEEK | 0.20, 0.04, 0.30, 0.005 and more | ¼” FNPT, 3/8” FNPT or Tube Stubs | Diaphragm Actuated for Gas and Liquid Control |

| BP8 |

High Flow Back Pressure Regulator |

500 PSIG | 0 – 250 PSIG up to 0 – 500 PSIG | Viton, PEEK or Glass-Filled PTFE | 1.20, 0.70 or 0.40 | ¼” FNPT, 3/8” FNPT, ½” FNPT or Tube Stubs | Diaphragm Actuated for Gas and Liquid Control |

| BP8LF |

High Sensitivity Back Pressure Regulator |

500 PSIG | 0 – 6 PSIG up to 0 – 500 PSIG | Viton, High Density PTFE, Polyimide, CF PTFE, Kalrez | 0.20, 0.04, 0.30, 0.005 and more | ¼” FNPT, 3/8” FNPT or Tube Stubs | Diaphragm Actuated for Gas and Liquid Control |

| BP66 |

Ultra High Back Pressure Regulator |

10,000 PSIG | 0 – 2,000 PSIG up to 0 – 10,000 PSIG | Polyimide or PEEK | 0.04, 0.12 or 0.01 | ¼” FNPT, 3/8” FNPT or Tube Stubs | Piston Actuated for Gas and Liquid Control |

*Most common selections have been listed and standardised options are highlighted in bold. For special options not listed please contact us.

Our regulators are also available with a huge variety of useful optional extras, including:

All of our GO regulators offer end users a unique set of features and benefits. Taking our time-tested and most popular PR1 series, for example, we can provide the following unique advantages over market-leading competitors:

For more information on the different advantages to end users and for detailed breakdowns of what models are best for gas/liquid use in various applications, please visit our blog post by clicking here.

We are committed to providing pressure regulators that meet the highest standards of safety and quality.

We carry a wide range of pressure regulators suitable to meet the requirements of many demanding industries, including nuclear, semiconductor, pharmaceutical, aerospace/defence, oil & gas and more.

We can offer pressure regulators that fulfil standards outlined in various certification documents and authorising bodies, including 3.1, 3.2, 2.1, 2.2, NACE, FDA, USP, TSE/BSE (ADI), Positive Material Identification (PMI), Helium Leakage Testing, High Pressure Testing etc.

Detailed reliability and safety information can be found on the pressure regulator’s technical datasheet.

Over the years we have been involved with many specialist and niche applications, providing completely customised and bespoke solutions tailored specifically to customer requirements.

Most recently, we worked in partnership with one of our customers who is a leader in fusion power research and sustainable nuclear energy solutions, and they approached us with some requirements for customised pressure regulator assemblies according to their specifications.

We delivered our CYL-20 dual-stage high cylinder pressure regulators, fitted with both standard mechanical 232.30 pressure gauges for visual confirmation and IS-3 ATEX Exia intrinsically safe pressure sensors for remote monitoring, suitable cylinder connectors and twin ferrule compression fittings, with interchangeable inlet ports for bottom or side entry possibilities.

We were able to act as a complete solution provider for our customer, to procure, supply, assemble and test all assemblies in-house at our headquarters. We are always happy to work with our customers on meeting bespoke requirements designed around specialist applications. Please reach out to our expert team if this is something you need assistance with.

We offer official and manufacturer-certified in-house servicing, testing and assembly of our core pressure regulators. We also provide bespoke panel and pressure regulator assembly solutions.

Our pressure regulator repair, servicing and testing service helps clients remain compliant with the British Compressed Gas Association’s suggestions about replacing or renewing regulators after a five-year operating period. With our service, we help clients diagnose the causes of a regulator failure in service and reduce costly downtime and replacement purchasing expenses. All regulators serviced or repaired by Boiswood are fully tested and certified.

Pressure is one of the most important process conditions to get right to ensure safe and stable operation, so it is important to specify the right pressure regulators. We have a vast selection of general-purpose and specialist, high-quality pressure regulators ready in stock, suited for a range of applications, media and environments. Get in touch with our experts for a consultation or explore our extensive catalogue to discover pressure-regulating solutions that you can rely on time and time again.

Pressure regulators are mechanical devices that control the upstream or downstream pressure of a fluid by responding to fluctuations in the system. These can be fluctuations in various process parameters such as pressure, temperature or flow. The goal of pressure regulators is to constantly maintain the desired pressure during normal or unexpected swings.

To maintain downstream pressure, a pressure regulator reduces the higher (and sometimes fluctuating) inlet pressure to a lower, steady outlet pressure by adjusting the valve opening. Unlike flow control valves that manage flow, pressure regulators specifically control delivery pressure.

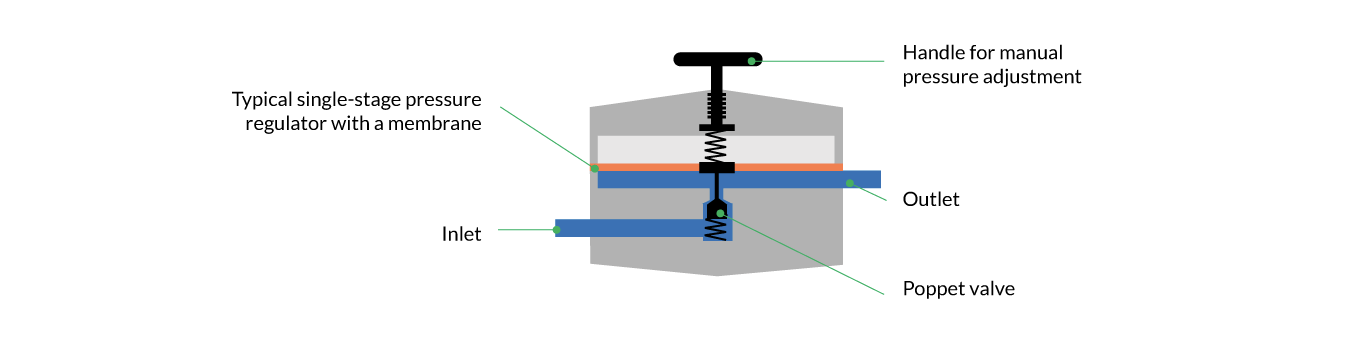

There are three functional components within a pressure regulator:

Loading element: acts on the sensing element and provides the force needed for the control element to act. It is usually a spring, but there are alternatives such as diaphragm or piston actuators.

Sensing element: usually a piston, diaphragm or membrane, the sensing element is used to sense pressure changes stemming from the force on the loading element as well as the pressure drop across the valve.

Control element: is the poppet valve that incorporates feedback from the other parts of the system to react and deliver the pressure reduction needed either upstream or downstream.

Find out more about how pressure regulators work and how to size one in our guide on pressure regulators.

Pressure regulators are widely used within domestic, analytical and industrial environments. Although there are many types on the market, most fall into two primary categories: pressure-reducing regulators and back-pressure regulators.

Pressure-reducing regulators provide steady and controlled downstream system pressure by reducing the higher inlet pressure.

Back-pressure regulators maintain upstream system pressure for all process users by controlling the inlet pressure.

Other types of pressure regulators include cylinder pressure regulators that regulate pressure over multiple stages to improve control accuracy, vaporising regulators and speciality regulators that have been designed for specific applications.

Whether you are looking for pressure regulators for analytical or industrial environments, our extensive range has everything you need with many available off-the-shelf in a variety of customisable configurations. Find out more about our pressure-regulating solutions in our handy online catalogue.

Pressure Regulators In Stock

Customisable Configurations

Official & Certified Partner

Sizing & Selection Guidance