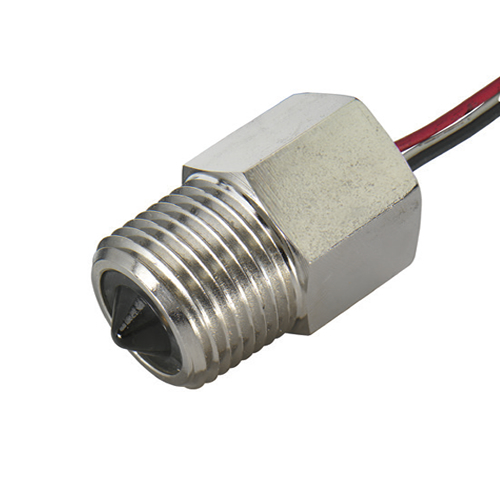

The all new ULS-200 level sensors for liquids are now available to order and have been designed as the perfect solid state point level measurement solution for installation in tank applications.

The all new ULS-200 level sensors for liquids are now available to order and have been designed as the perfect solid state point level measurement solution for installation in tank applications.

Primarily designed as a water level sensor, this unit can also be supplied with an alternative probe for use on hydrocarbon liquids (eg. for use as an oil level sensor).

This new all-in-one technology liquid level sensor is a 'must-have' solution for any tank installation where monitoring water level control is critical.

Universal Level Measurement Solution for Tanks

The ULS-200 advanced sensor technology encapsulates the best of what many existing level sensor types offer into one single unit.

The following is a comparison of existing level sensing technologies and their advantages and disadvantages:

| Model Example | Technology Type | Pros/Advantages | Cons/Disadvantages |

|

CAP-300 |

|

|

|

|

ELS-1150 |

|

|

|

|

XLS-1 |

|

|

|

|

LS-7 |

|

|

The ULS-200 incorporates the best advantages of all the above mentioned technologies into one single unit:

| Category/Type | Sensor Attributes |

Float Type |

Capacitive Type |

Electro-Optic Type |

Ultrasonic Type |

ULS-200 |

| Media Detected | Aqueuous | Yes | Yes | Yes | Yes | Yes |

| Media Detected | Hydrocarbon | Yes | No | Yes | Yes | Yes |

| Media Detected | Low Dielectric | Yes | No | Yes | Yes | Yes |

| Environmental | High Humidity | Yes | Yes | No | Half | Yes |

| Environmental | High Pressure | Yes | Yes | Yes | Yes | Yes |

| Environmental | High Reflection | Yes | Yes | No | Yes | Yes |

| Environmental | High Viscosity | No | Yes | Half | Half | Yes |

| Special Considerations | Build-Up Prevention | No | Yes | Half | Half | Yes |

| Special Considerations | Mounting Orientation | No | Half | Half | Half | Yes |

| Special Considerations | Time Delays | No | No | No | No | Yes |

"Yes" = Fully Supports, "Half" = Somewhat Supports, "No" = Does Not Support

Standard Level Sensor Configurations

At Boiswood, we have consolidated the ULS-200 standard options into "easy-to-order" configurations:

| Actuation Condition | Brass - 1/4" NPT | Brass - 1/2" NPT | Brass - M12 x 1.5 | Brass - G1/4" | 316L SS - 1/4" NPT | 316L SS - 1/2" NPT | 316L SS - M12 x 1.5 | 316L SS - G1/4" |

| Wet Sink | 8015117 | 8015118 | 8015119 | 8015120 | 8015121 | 8015122 | 8015123 | 8015124 |

| Dry Sink | 8015125 | 8015126 | 8015127 | 8015128 | 8015129 | 8015130 | 8015131 | 8015132 |

| Wet Source | 8015133 | 8015134 | 8015135 | 8015136 | 8015137 | 8015138 | 8015139 | 8015140 |

| Dry Source | 8015141 | 8015142 | 8015143 | 8015144 | 8015145 | 8015146 | 8015147 | 8015148 |

Above configurations are standard for Water media, without time delay and with Integral Deutsch DT04-3P connector. For additional non-standard options please contact Boiswood.

Off Highway Vehicle Success Story

In the demanding world of heavy off-highway (OHV) equipment, level sensors are critical components that must endure some of the harshest environmental conditions possible. From construction sites to mining operations, these sensors can be required to withstand fluctuating temperatures, dust/ingress and vibrations. Withstanding these environmental factors is crucial to maintaining equipment reliability and operational efficiency.

Industry Challenges

Level sensors installed in heavy OHV equipment face harsh outdoor environmental conditions:

- Temperature variations - this equipment can be required to function under extreme temperature fluctuations ranging from -40°C to 50°C. This can cause sensor failures and inaccurate readings.

- Dust and Ingress - these industries often operate in dusty and dirty environments. Dust and debris can interfere with sensors, causing them to malfunction or fail, whilst ingress of water can corrode sensors.

- Vibrations - heavy equipment often vibrates during operation, which can damage or displace sensors. This can lead to inaccurate readings or complete sensor failure.

Our Solution

To overcome these challenges, level sensors installed in such equipment must be designed to withstand harsh environmental conditions. The sensors must be sealed against dust and moisture, and they should be shock-resistant and vibration-proof. They should also have a wide operating temperature range and be able to withstand electrical interference. Additionally, regular maintenance and calibration of the sensors are essential to ensure accurate readings and prevent failures.

- The ULS-200 point level sensor has a sealed construction that meets the IP6k9k rating for high-pressure wash-downs. It can operate in a wide temperature range of -40°F to +257°F (-40°C to +125°C) and a high-pressure range of 300 PSIG (20 bar). Moreover, the ULS-200 is insusceptible to vibrations, making it the perfect choice for mobile applications.

- The ULS-200 can be configured to meet your specific application needs, with additional options for time delays. This feature is especially useful for mobile equipment to prevent false signals caused by sloshing or turbulence. Time delay functions are available on request.

- The ULS-200 level sensor employs solid-state output for point-level sensing with high accuracy and repeatability. Unlike common float-type switches that are prone to wear and tear, this sensor has no mechanical moving parts and lasts much longer.

Overall, the ULS-200 point level sensor is an excellent choice for those looking for a long-lasting, reliable sensor that can operate in the harshest conditions.

Types of Level Sensors

Our single point level sensors are ideal for reliable and accurate tank level detection. Our liquid level sensors are available in a vast range of sizes, mountings, materials and sensing technologies (from mechanical to no moving parts) which include float type sensors and switches, electro optic level switches, capacitive level sensors and switches and ultrasonic level sensors.

For more information on the various types of level sensors available and how they could serve your application, please follow our guide here.

Application Examples

In addition to general tank level control and sensing applications, the ULS-200 can be considered for the following industries:

- Construction - such as monitoring engine oil level on off-highway vehicles.

- Emergency Vehicles - such as monitoring radiator coolant levels on fire trucks.

- Buses & Recreational - such as measuring washer fluid level.

- Agriculture - such as monitoring transmission fluid consumption in tractors.

- Water & Waste Water Treatment - such as monitoring tank levels.

- Power Generation - such as monitoring hydraulic oil levels in generators.

- Renewable Energy - such as sensing liquid or condensate levels in knockout pots.

- HVAC/R - such as monitoring water levels in coolant circuit loops.

Other Level Solutions

Moving away from the single point level sensing range, we can also help with:

- Multiple Point Level Sensors & Switches - including point stainless steel level sensors and plastic level sensors.

- Level Meters & Transmitters - for continuous measuring in tanks, with technologies include ultrasonic level, guided waver radar, rotating vane, reed type and magnetostrictive.

For our full range of level measuring solutions please visit our category page here.

Why Use Gems Sensors?

The key focus from Gems Sensors is to support customers with the best product solution. To achieve it, they apply a wealth of tools and global resources that include:

- A dedicated team of application engineers and specialists, with over 50 years' experience in industry, who specialise in developing bespoke solutions to meet customer demands.

- An extensive product portfolio of thousands of proven designs, that reduce time required for end users to deliver a complete solution.

- Working closely with official distributors like Boiswood to provide expert knowledge in fluid level, flow, pressure sensors, controls, solenoid valves and associated fluidic systems.

- Utilising the resources of a Fortune 500 company, Gems can maintain their long-standing commitment to quality, lean manufacturing and ISO certification.

- Dedicated tools and processes that eliminate product and process variation at every stage of manufacturing (monitoring aspects such as DFMEA and PFMEA).

Not sure if these are right for you? For additional information on the types of level sensors available on the market, please visit our blog by clicking here.

Need some guidance? Contact our experienced technical team here for application support and advice on components for your system.