The journey from elementary indicators to today's fully automated, data-driven room pressure monitoring systems showcases the continuous commitment to patient safety and infection control in medical facilities, progressing towards Hospital 2.0 environments. All of the technological advancements have played a pivotal role in ensuring a safer environment for patients, healthcare providers/medical staff, and visitors alike.

With the rapid advancement of technology, room pressure monitoring is constantly moving through revolutionary transformations. Digital and automated systems are emerging, offering more sophisticated and comprehensive solutions.

HTM 03-01 and HBN 04-02 Regulations

Working towards building Hospital 2.0 settings, we have a tailored portfolio of solutions that are designed to fit and operate within Heath Technical Memorandum 03-01. This memorandum is specifically focused around specialised ventilation for healthcare premises, such as isolation facilities for infectious patients in acute settings.

For example, our LITE visual pressure indicator meets the following standards/regulations outlined in HTM 03-01:

- Acts as a critical component for controlling/monitoring room pressure in relation to adjacent spaces as a differential pressure monitor (2.13 Supply and Extract Ventilation).

- As above, ensures pressure is stabilised to prevent reversal of air flows in operating theatres, isolation wards and clean rooms/facilities (5.74 Pressure Stabilisers - Size and Location).

- Local visual display showing live pressure readings allows end users to accurately monitor the condition of the air (6.13 Automatic Controls - Location of Controls).

- Easy-to-use push button menu (3 buttons) to freely select and program the unit according to specific requirements and parameters, directly mounted onto the unit itself (6.17 Automatic Controls - Location of Controls).

- Allows facilities to control the system or room pressure, monitors/indicates the operating state and alarms to indicate failure, low air flow and filter state (6.2 Automatic Controls - General Requirements).

- Quick-read LED light ring/indicator allows fast confirmation of the operational status of the system (6.48 Automatic Controls - Alarms and Indication).

- Allows programmable set point (audible and/or visual alarm) with timer delay, to work based on a predetermined pressure level and not allowing supply-air quantity to fall below design values (6.7 Automatic Controls - General Requirements).

- Output signal (4 to 20 mA, 0 - 5 V, 0 - 10 V field selectable) allows feedback to control the system via a BMS building management system (6.9 Automatic Controls - General Requirements).

- Bidirectional pressure monitoring (positive and negative) to ensure correct air flow direction through doorways (7.57 Door Protection).

- Possibility to integrate with additional environmental monitors or continuous environmental monitoring software solutions to have fully sophisticated cloud-based monitoring solutions (7.74 Automatic Control).

- High accuracy ratings ensures that nominal room pressure guidelines can be fully adhered to with confidence (Appendix 3 - Hierarchy of Cleanliness).

In addition to the above, we can also adhere to standards outlined in Health Building Note 04-02 for critical care units, relating specifically to ICU/CCU standards. Most notably, this documentation give guidelines for the provision of Intensive Care Services.

We have worked closely with NHS trusts across the UK (including Authorising Engineers) to facilitate room pressure monitoring solutions with HBN 04-02 in mind:

- We can help with negative pressure room spaces and can provide you with the link here to our separate guide on how best to achieve and monitor this (2.11 Negative Pressure Room).

- Having local visual, audible alarm and analogue/voltage output options integrated into one unit allows for all bases to be covered, including relay to a designated nurses station, as well as monitoring via BMS to estates department (2.19 Monitoring and Record Keeping).

- We can provide versions in quick mounting kits, portable units and construction kits to allow for validating rooms during a construction/redesign phase or temporary setups (A2.3 Validation).

- We can supply additional equipment such as particle counters and air quality monitors to ensure compliance with BS EN 1882 (A2.6 Filtration Test Standards).

- High accuracy and repeatability ensures air change rate (ACR) of 10 per hour is met, supply/extract fan monitored locally and remotely, BSRIA/BTS2 test standards procedures to follow soon (A2.12 System Operating Standard).

Modern and Holistic Measuring Solutions

Through our specialised healthcare monitoring portfolio, we have got you covered for:

- Digital Manometers - digital manometers are starting to phase out the old style of analogue/dial gauges, providing end users with real-time pressure readings with greater precision and reliability. These devices, such as the Setra LITE pressure monitor, allow for continuous monitoring of room pressure and seamless integration with building management systems.

- Automated Controls - fully automated room pressure control systems are starting to become the 'go-to' choice. These systems utilise advanced differential pressure sensors and BMS feedback loops to constantly monitor and adjust the air pressure in different rooms. They are often integrated with central building automation systems, enabling remote monitoring and control, such as the Setra FLEX environment package.

- Smart Alarms and Notifications - modern room pressure monitoring systems are equipped with smart alarms and visual notifications. Healthcare professionals can receive immediate alerts if pressure differentials deviate from the desired range, even through the room pressure monitors themselves, allowing for quick responses and ensuring patient safety.

- Data Logging and Analytics - the integration of data logging and analytics capabilities in modern systems has enabled healthcare facilities to track historical pressure data, identify trends, and optimise ventilation strategies for improved efficiency and infection control. This can be achieved through our Setra CEMS continuous environmental monitoring package.

- Wireless and Mobile Solutions - some systems have transitioned to wireless and mobile applications, providing increased flexibility and convenience for monitoring pressures from various devices and locations within the facility. We can offer solutions for pressure, temperature, relative humidity (RH), particle counters, door count and more.

Differential Pressure Monitoring

Our LITE room pressure monitor is the 'go-to' solution for any medical facility looking to optimise their processes to Hospital 2.0 standards.

In the height of COVID-19, Boiswood helped develop the Setra Lite from a basic differential pressure sensor, to a fully-equipped solution designed to help save lives.

Some of the latest additional features for the unit include:

- Sounding Alarm that can be toggled on/off at will, with delay timer functionality.

- Dual Alert Display to provide visual indication inside and outside the measuring space.

- Rotatable Display and Faceplate Options to allow portrait or horizontal installation with black or white colours to suit the location.

We have helped to design this solution around years of engineering research and customer feedback, to provide end users with a complete solution to stage as an upgrade to any existing Magnehelic® pressure gauges with ease.

The LITE is perfect for meeting guidelines set out in HTM 03-01 and HBN 04-02 documentation.

Environmental Monitoring Solutions

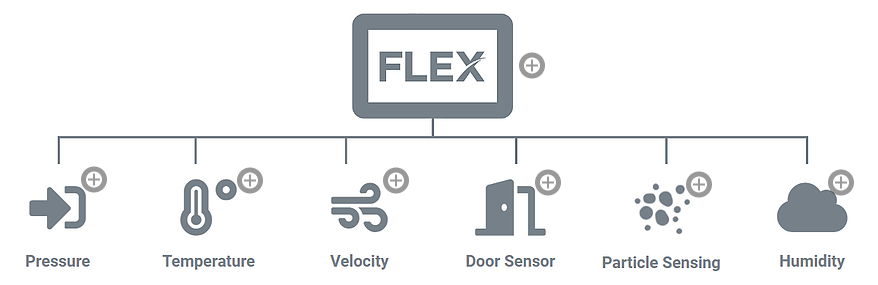

To go a level further, customers can also consider our FLEX environmental monitor and controller.

Designed to support inputs from 3 different rooms, up to 6 parameters for each room, this solution is perfect for easy integration with any building automation systems through BACnet/IP or BACnet MS/TP network protocols.

Some of the latest additional features for the unit include:

- Improved Modular Design allows the monitor to fit in various wall thicknesses around the globe, making it easy and cost-effective to install.

- Available with on-board sensor to maximise on efficiencies and gain full monitor/control capabilities straight away at the install location.

- Modern network/communication protocols to allow integration into existing BMS/BEMS/BAMS installations, available with an additional range of hardware and software solutions to fit your facility.

NHS and Healthcare Ventilation Applications

Specialised Ventilation Systems can include:

- Operating Theatres (including conventional and UCV theatres).

- Treatment Rooms (including endoscopy, cardiology, imaging suites, barn theatres and recovery areas).

- Critical Areas (including maternity theatres and birthing rooms).

- Isolation Facilities (including infectious disease units, transplant units, chemotherapy and oncology units).

- Sterile Service Departments (including wash rooms, pharmacies, inspection and storage rooms).

- Other Specialty Departments (including pathology, mortuaries, hydrotherapy units, burns theatres, gene therapy units and stem-cell laboratories).

Summary

For our full range of product solutions, please click here to start your HVAC/R journey and learn more about what we can offer.

To watch some videos on our LITE and FLEX products in action, as well as some detailed overviews on the sensing technologies we use, please click here to visit our YouTube channel.

Prefer to have something to read offline later? Please click here to download our HVAC/R guide in PDF format.

Still not sure where to look? Please get in touch with us today to discuss how we can help you.