As a family-run business acting globally, with 10,200 highly qualified employees, the WIKA group of companies is a worldwide leader in pressure and temperature measurement. WIKA also sets the standard in the measurement of level, force and flow, and in calibration technology.

WIKA Digital Switches

Developed as compact, intuitive and integrated solutions, WIKA have now have digital electronic switches available for pressure, flow and temperature measurement (the PSD-4, TSD-30 and FSD-4 family). These units have all been designed as flexibly configurable, integral local displays, scalable outputs and easy to setup.

During development of the WIKA switch family, a high value was placed on a robust design and the selection of appropriate materials suited to machine-building and industrial applications. For this reason, the case housing and the threaded process connection of the electrical connector are completely made from stainless steel. Overwinding or tearing off the connector is therefore virtually impossible.

Digital Pressure Switch

The model PSD-4 digital pressure switch represents the extensive further development of the WIKA electronic pressure switch family. It has already been awarded with the “iF product design award” for its outstanding functionality. The unit boasts a high accuracy of 0.5%, freely configurable output signals (including PNP/NPN, 4 to 20 mA/0 to 10 V), the 5:1 turndown scalability of the analogue output, in addition to outstanding self-diagnostics, makes the PSD-4 an excellent automation solution.

The installation of the PSD-4 can be flexibly adapted to the individual mounting requirements of a system and is ideal to act as either an air pressure switch or water pressure switch. Due to the almost unlimited rotation of the digital display and case by more than 300°, the digital display can be adjusted independently of the electrical connection. The digital display can thus always be aligned to face the operator, and the M12 x 1 electrical connection positioned to suit the desired cable routing.

With the optional output signal in accordance with the IO-Link communication standard, the PSD-4 electronic pressure switch allows a fast integration into modern automation systems. IO-Link offers simpler and faster installation, parameterisation and higher functionality for the PSD-4.

For an overview of the products features and benefits, please watch our introductory video below:

Digital Flow Switch

The model FSD-4 digital flow switch offers full flexibility in monitoring and controlling flow based on the velocities of liquid media. The switch points of this universal flow switch can be freely configured very easily via the 3-button operation directly on the instrument or optionally via IO-Link. The model FSD-4 can output both absolute values in various units and relative flow values and display them on the digital indicator.

The flow is determined by many factors such as the pipe diameter, the system set-up or the medium. Therefore, depending on the application, the actual flow value may differ from the calibrated value. Thanks to the teach function, this water flow switch can be set to the zero point and the maximum flow at the respective measuring location and thus optimally adjusted to the measuring conditions. The compression fitting on the flow switch offers additional flexibility. Depending on the pipe diameter, the immersion depth and alignment can be individually adjusted.

The parameters are set either via 3-button operation on the instrument or, optionally, via IO-Link. When changing the instrument, the settings for the respective measuring location can be transferred directly to the new flow switch. This eliminates the need for any repeat parameterisation at the measuring location and reduces the necessary integration effort. With IO-Link, additional functions such as an operating hours counter or max value memory can be called up and used for condition monitoring.

Digital Temperature Switch

The model TSD-30 digital temperature switch features a robust LED display which has been designed using 9 mm high characters (the largest possible) and with a slight incline to make reading the temperature as easy as possible from a long distance away. A 14-segment display has been used to represent text very clearly.

The 3-key operation makes simple, intuitive menu navigation possible, with no need for additional assistance. The menu navigation is designed in accordance with the latest VDMA standard. The VDMA standard for fluid sensors (24574-2, part 2 temperature switches) has the aim of considerably simplifying the use of temperature switches by standardising menu navigation and display.

The control keys have been designed as large as possible and are arranged ergonomically to ensure fast and easy adjustments. Operation without any additional assistance is made easier through the tactile feedback.

Applications

These versatile and highly intuitive family of electronic switches are suitable for a broad setting of industries and applications, including:

- Machine Tools

- Hydraulics and Pneumatics

- Pumps and Compressors

- Machine Building and Factory Automation

- Coolant Circuits and Lubrication Systems

- Control and Monitoring of Filtration Systems

Other WIKA Solutions

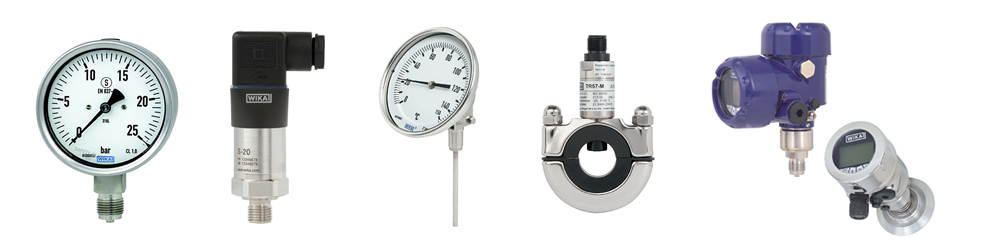

We are also here to support the full extensive portfolio of WIKA, including their world-class range of pressure and temperature solutions.

- Pressure Gauges – including bourdon tube pressure gauges, test gauges, diaphragm pressure gauges, capsule pressure gauges, differential pressure gauges, absolute pressure gauges and digital pressure gauges.

- Pressure Sensors – including pressure sensor assemblies and modules, OEM pressure sensors and process transmitters.

- Temperature Monitoring – including dial thermometers, thermocouples, resistance thermometers and thermowells.

Your WIKA Partner

Our enormous portfolio features an extensive range of options, technologies and configurations to meet the most demanding applications. To explore our full range of product solutions solutions from WIKA, please visit our landing page here.

For technical support on selecting the right sensor for your application, get in touch with our experienced engineers here.