Over the past 75 years, WIKA has built a reputation as a distinguished manufacturer and competent specialist for any task in the field of measurement technology. Based on steadily growing efficiency, innovative new technologies are applied when developing new products and system solutions. The reliability of the products and the readiness to face all challenges of the industries served have been the key factors for WIKA to achieve a leading position in the global process and instrumentation markets.

Your Trusted & Official Premium Partner

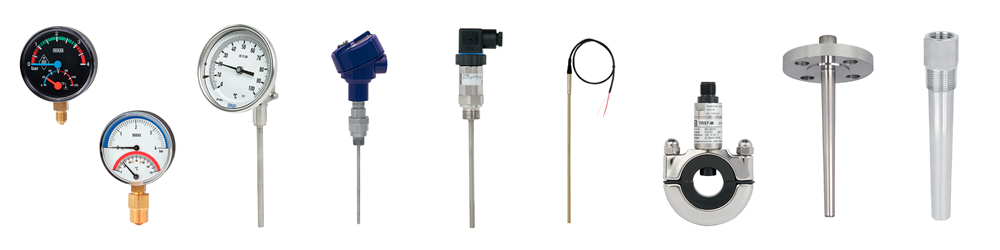

The WIKA programme is divided into several product lines and is thus suited to fulfil requirements of the widest range of applications, including pressure gauges, sensors & transmitters, level & temperature measurement solutions, force transducers & calibration equipment.

WIKA Instruments Limited is the UK subsidiary of the world’s leading manufacturer of pressure, temperature, level, flow and related calibration instruments.

For a brief overview on the history of WIKA, please watch our below video:

WIKA Pressure Gauges

Our pressure gauges (mechanical pressure measuring instruments) for gauge, absolute and differential pressure have been proven millions of times over. For the optimal solution for the widest range of applications, there is a choice of measuring systems in bourdon tube, diaphragm element and capsule element technologies.

The pressure gauges cover scale ranges from 0 to 0.5 mbar to 0 to 6,000 bar and indication accuracies of up to 0.1%. For the various requirements in industrial and process instrumentation there are pressure elements from copper alloys, stainless steel or special materials available. Our gauge types include:

- Bourdon Tube Pressure Gauges – typically available in either copper alloy or stainless steel construction for either liquid or gaseous media. For copper alloy construction, scale ranges cover pressures for 0.6 to 1,000 BAR and are manufactured in accordance with European standard EN837. For stainless steel construction, scale ranges cover from 0.6 to 7,000 BAR, are suitable for aggressive media/environments and depending on the model can have an overload safety of up to 5 x full scale value.

- Test Gauges – for the highest accuracy requirements, depending on the instrument model, accuracies of 0.1, 0.25 or 0.6% of full scale value can be measured. The pressure ranges cover from 0 to 6 mBAR to 0 to max. 1,600 BAR and are suitable for calibration tasks. For each of the pressure gauges specified here, a DKD/DAkks certificate can be provided if required.

- Diaphragm Pressure Gauges – these gauges are the specialists in the process industry when it comes to critical measuring tasks such as with highly corrosive or viscous media or when it comes to low pressures and high overload. The scale ranges are from as low as 0 to 16 mBAR to typically 0 to 40 BAR, with higher overload safety values and special designs for aggressive media available.

- Capsule Pressure Gauges – these measuring instruments are particularly suited to gaseous media. The scale ranges are between 0 to 2.5 mBAR and 0 to 1,000 mBAR in accuracy classes from 0.1 to 2.5. Capsule pressure gauges consist of two circular, corrugated diaphragms, joined together around the edge with a pressure-tight seal, making them highly popular within medical, vacuum, environmental and laboratory technology.

- Differential Pressure Gauges – these gauges work with a wide range of pressure elements. With this variety, measuring ranges from 0 to 0.5 mBAR to 0 to 1,000 BAR and static overlay pressures up to 400 BAR are possible. They are commonly used for filter monitoring, closed vessels and clean room overpressure.

- Absolute Pressure Gauges – these gauges are used when measured pressures are independent of the natural fluctuations in atmospheric pressure. The pressure of the measured media is determined against a reference pressure, which corresponds to the absolute pressure zero point. For this, the reference chamber is completely evacuated, so that there is a near-perfect vacuum in it.

- Digital Pressure Gauges – these units show the acting pressure in an integrated digital display. The indicator cases of our digital pressure gauges are rotatable if required and thus always ensure a good readability. In addition, intrinsically safe versions and instruments with wireless interface are available.

WIKA Pressure Sensors

A pressure sensor (or pressure transmitter) converts the physical quantity 'pressure' into an industry-standard signal. In addition to a wide range of pressure sensors for general industrial applications, we offer special versions for refrigeration/air conditioning technology, the food industry, mobile working machines, medical gases and also the semiconductor industry.

Our pressure sensor, pressure transmitter and contact pressure gauge portfolio covers accuracies from 0.05%, measuring ranges from 0.05 bar up to 15,000 bar, digital interfaces such as CANopen and IO-Link and also various international approvals, including for hazardous areas. Our various subcategories include:

- Pressure Sensor Assemblies and Modules – ranging from OEM and industrial pressure sensor solutions, through to refrigeration, air-conditioning and Hydrogen application specific units, to sanitary and ultra-high purity with ATEX intrinsically safe and explosion-proof approvals, we have a solution to keep you covered.

- Pressure Gauges with Output Signal – the multi-functional intelliGAUGEs present a cost-effective and reliable solution for nearly all pressure measurement applications. They combine the analogue indication of a mechanical pressure gauge, needing no external power, with the electrical output signal of a pressure sensor. These hybrid instruments are available with all commonly used electrical signals. The sensor works in a non-contact way, without any influence on the measuring signal.

- Contact Pressure Gauges – control systems are gaining more and more importance in industrial applications and the measured value must be transferred to the control system via an electrical signal, eg. by closing or opening of a circuit. Depending on the model, we can help with many different contact types including magnetic snap-action, inductive, electronic, reed, micro and transistor.

- Process Transmitters – suitable for many industrial measuring requirements, these units differentiate themselves from pressure sensors through their increased range of functionality; they feature integrated displays, offer high measurement accuracies and freely scalable measuring ranges, communicate via digital bus signals and can be delivered with a multitude of case variants.

WIKA Temperature Gauges

Our temperature portfolio covers everything from simple dial gauges, thermometers with switch contacts all the way through to fully assembled resistance thermometers with integrated thermowells and temperature controlling solutions.

The main subcategories we cover include:

- Dial Thermometers – our dial thermometers work on the bimetal, expansion or gas actuation principle. This enables scale ranges of -200 .to +700°C in different class accuracies, response times and resilience to environmental influences. These are all available with diverse connection designs, stem diameters and individual stem lengths to enable a flexible measuring point design.

- Thermocouples – these units generate a voltage directly dependent on temperature. They are particularly suitable for high temperatures up to 1,700°C (3,092°F) and for very high oscillating stresses. For thermocouples, the accuracy classes per IEC 60584-1 and ASTM E230 apply.

- Resistance Thermometers – our resistance thermometers are equipped with platinum sensor elements which change their electrical resistance as a function of temperature. In our range of products you will find resistance thermometers with connected cable as well as versions with connection head. A temperature transmitter can be installed directly in the connection head.

- Thermowells - whether in aggressive or abrasive process media, whether in high or low temperature ranges: for electrical or mechanical thermometers, to prevent direct exposure of their temperature probes to the medium, thermowells/protection tubes that suit each application are available. Thermowells/protection tubes can be machined from bar stock material or assembled from tube sections and can either be screw-, weld or flange fitted.

Other WIKA Products

We are also here to support the full extensive portfolio of WIKA, including the level, flow and force product categories.

- The level portfolio includes bypass indicators, submersible pressure sensors, float switches, optoelectronic switches, sight glass indicators and external chambers.

- The flow portfolio includes flow switches, ultrasonic flow meter, magnetic inductive flow meters and elements.

- The force portfolio includes load cells and pins, ring & compression force transducers, inclination sensors and bending beams.

WIKA UK

Our enormous portfolio features an extensive range of options, technologies and configurations to meet the most demanding applications. To explore our full range of product solutions solutions from WIKA, please visit our landing page here.

For technical support on selecting the right sensor for your application, get in touch with our experienced engineers here.