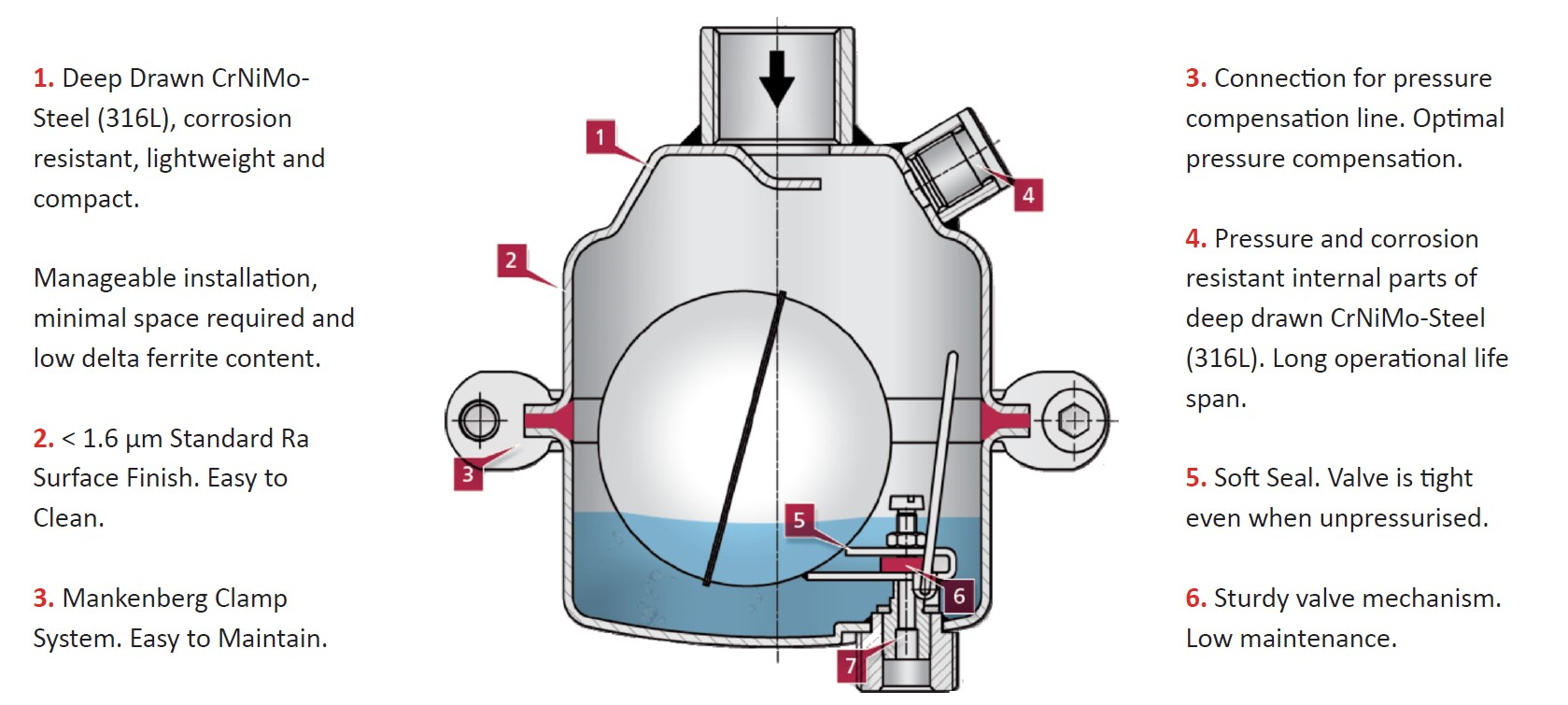

Our KA2 ATEX condensate trap has been specially designed for draining compressed air and gases in biogas applications. These units are float-controlled condensation traps (also known as autodrains) for use in potentially explosive atmospheres (ATEX Zones) and is particularly suitable for aggressive condensates and hazardous media. It is completely made of deep-drawn stainless steel with excellent corrosion resistance properties. The valve is soft-sealed and is completely gas-tight.

Our KA2 ATEX condensate trap has been specially designed for draining compressed air and gases in biogas applications. These units are float-controlled condensation traps (also known as autodrains) for use in potentially explosive atmospheres (ATEX Zones) and is particularly suitable for aggressive condensates and hazardous media. It is completely made of deep-drawn stainless steel with excellent corrosion resistance properties. The valve is soft-sealed and is completely gas-tight.

Safety Is A Choice You Make

These explosion proof steam traps autodrain condensate without any loss of steam or gas. They operate instantaneously and are not affected by back pressure or pressure fluctuations, and their simple mechanical design means they do not require an external energy input.

The top and bottom sections of the valve body are connected by a clamp ring and two bolts for extremely easy servicing and maintenance without any requirement for special tooling. The simple design makes it easy to specify, install, handle and service these valves in an industrial environment where there may be ATEX, DSEAR, HAZOP or OPMAN requirements.

In various biogas and anaerobic digestion facilities, our condensate traps are used for the automatic water drainage of knockout pots or gravel/fine ceramic filters. The condensate pit poses a high risk due to the concentrated accumulation of CH4, CO2 or H2S. Insufficient protection against the escape of this hazardous media poses a dangerous risk.

Hydrogen Sulphide (H2S) has an extremely corrosive effect on materials of pipelines, valves or tanks, because it forms sulphurous acid when reacting with water or vapour. This leads to “Hydrogen Induced Cracking”, during which the hydrogen released by the chemical reaction diffuses into the steel and causes cracks. Our corrosion-resistant and deep-drawn stainless steels are the best materials available for selection in biogas plants. Additionally, the selected valves must be frost-proof and ATEX compliant.

Our safe condensate traps have been specified in a number of Thermal Hydrolysis Plants (THP), Advanced Energy Recovery (AER) and Waste Water Treatment (WWT) projects. All of these are forward thinking, advanced technologies that will help towards a greener and energy efficient economy. For more information on how we can help you and your facility, get in touch.