Pressure regulators play a crucial role in controlling fluid pressure in most industrial operations. They are designed to maintain consistent and safe pressure levels within process piping and equipment. Being such a critical instrument, understanding how to properly size, select and install them is key to ensuring optimal system performance. In this blog, we will explore the basic principles of pressure regulators, their types, applications and the factors to consider when specifying them for different process needs.

GO Regulators

For over 50 years, our partner GO Regulator has been a leading designer and manufacturer of standard and custom single/two stage pressure regulators, back pressure regulators and heated vaporising pressure regulators for the Analytical Instrumentation, Petrochemical, Oil & Gas and Specialty Gas markets.

Today, GO continues to offer a versatile line of time-proven products designed to fulfil a wide range of typical and bespoke gas and liquid application requirements. In several series, a standard 316L body material is used to facilitate a variety of threaded/welded connections, with optional materials of Brass, Monel®, Hastelloy® C-276, or Titanium construction being offered.

In addition, a variety of seat materials, orifice sizes and pressure control ranges allow the end user to utilise our models for a broad spectrum of capabilities. The “customer focused” philosophy, supported by experienced people enables GO Regulator to persevere in providing viable product solutions to the challenging applications of today at competitive prices.

Core Pressure Regulator Models

Virtually all requirements involved for many applications can be fulfilled with approximately fifty GO fluid control product models and associated optional features. Below we are highlighting some of the key/core models for most tasks. For our complete range of GO products please click here.

|

PR1/PR2 Series |

PR7/PR7LF/PR7ULF Series |

PR50/PR57/PR59 Series |

CYL2/CYL20 Series |

|

BP3 Series |

BP8/BP8LF Series |

BP60/BP66 Series |

SPR/SBPR Series |

|

CPR1/CBP3/MR1 Series |

HPR2/CV/DHR Series |

PR9 Series |

COM2B Series |

Types & Variations

There are lots of different types of regulators that can be used for different tasks in a variation of applications. For example, a pressure-reducing regulator is best suited to protect sensitive downstream components or precisely control a pressure-sensitive process. Another example is a back pressure regulator, which is ideal for maintaining a constant pressure upstream of the regulator, such as in a reactor vessel where a specific pressure must be held to ensure optimal reaction conditions.

For further details and a full breakdown of how the following types of pressure regulators work, please visit our blog post by clicking here.

- Pressure Reducing

- Back Pressure

- Cylinder Pressure

- Vaporising/Heated

- Specialty Units

Flow Sizing

For an itemised list of information on what is needed to correctly size, select and specify a regulator, please reference the below checklist:

| 1 | Pressure Regulated* | Pressure Reducing or Back Pressure? |

| 2 | Type of Regulation | Line or Bottle? |

| 3 | Preferred Materials | 316L, Brass, Monel®, Hastelloy® or Other? |

| 4 | Upstream Pressure (P1)* | Eg. in PSIG/BARG (Min/Normal/Max) |

| 5 | Downstream Pressure (P2)* | Eg. in PSIG/BARG (Min/Normal/Max) |

| 6 | Flow Rate (Q)* | Eg. in SCFM/LPM (Min/Normal/Max) |

| 7 | Temperature (T)* | Eg. °C/°F (Min/Normal/Max) |

| 8 | Media (M)* | Eg. Nitrogen/Air/Argon/Water |

| 9 | Line Size/Connection Size | Eg. ¼” or ½” |

| 10 | Preferred Connection Type | Eg. NPT, BSPP, VCR, Tube OD Compression |

| 11 | Flow Direction | Eg. Left to Right or Right to Left |

| 12 | Mounting | Base Mounting, Panel Mounting or None? |

| 13 | Pressure Indicators? | Are Pressure Gauges or Sensors needed? |

| 14 | Fittings or Connectors? | Are Cylinder Connectors or Adapters needed? |

| 15 | Other Accessories? | Any Flexible Hoses, Relief Valves, Filters or Other? |

| 16 | Application Details | Eg. For a Nitrogen Gas Cylinder |

| 17 | Special Notes/Requirements | ?? |

*Minimum required information has been marked with an asterisk.

For more detailed considerations on how to size and select a pressure regulator, including flow coefficient (Cv) and max. flow rate calculation tools, please click here to download our sizing brochure. Our calculation tools allow you to correctly select the required flow coefficient (Cv) value for your pressure reducing or back pressure units. These software tools will utilise your process data to calculate the Cv so that you can achieve your required flow rate.

Some of the most common flow formula abbreviations and definitions include:

- Cv - Flow coefficient for regulators and valves that expresses flow capabilities of a unit at fully open condition. For liquids, this coefficient is defined as the flow of water at 60°F in gallons per minute at a pressure drop of one PSIG. For gases, this coefficient is defined as the flow of air at standard conditions in standard cubic feet per minute for each PSIG of inlet pressure.

- SL - Specific gravity of liquids relative to water, both at standard temperature of 60°F. (Specific gravity of water = 1.0 @ 60°F).

- Sg - Specific gravity of a gas relative to air; equals the ratio of the molecular weight of the gas to that of air. (Specific gravity of air = 1.0 @ 60°F).

- P - Line pressure (PSIA).

- P1 - Inlet pressure expressed in PSIA.

- P2 - Outlet pressure expressed in PSIA.

- DP - Differential pressure (P1 – P2).

- PSIA - Absolute pressure which is gauge pressure (PSIG) plus 14.7 (atmospheric pressure).

- QL - Liquid flow in gallons per minute (GPM).

- Qg - Gas flow in standard cubic feet per minute (SCFM). (At standard conditions of 60°F and 14.7 psia).

- Q - Volume flow rate in cubic feet per minute (CFM).

- M - Mass flow rate in pounds per minute (lbs/min).

Installations & Applications

Our GO pressure regulators are used in an enormous selection of applications and industries, from industrial to analytical/high-tech to UHP environments. Some of the most regular industries and applications we work with can include:

- Chemical & Petrochemicals – including research laboratories, coating systems and pilot plants.

- OEM Equipment & Machinery – including pollution control equipment, gas analysers, test stands, oil and gas control skids and gas turbine controls.

- Oil & Gas – including well heads, pipeline transportation, oil and gas exploration, offshore platforms or refining facilities.

- Power Generation – including fossil fuel power generation, nuclear power plants, specialty gas and steam plants.

- Pulp & Paper – including batch or continuous processing, fluid transfer, mixing or plant utilities.

- Calibration Gas – including sample conditioning systems, gas blanketing systems and pressure let down stations.

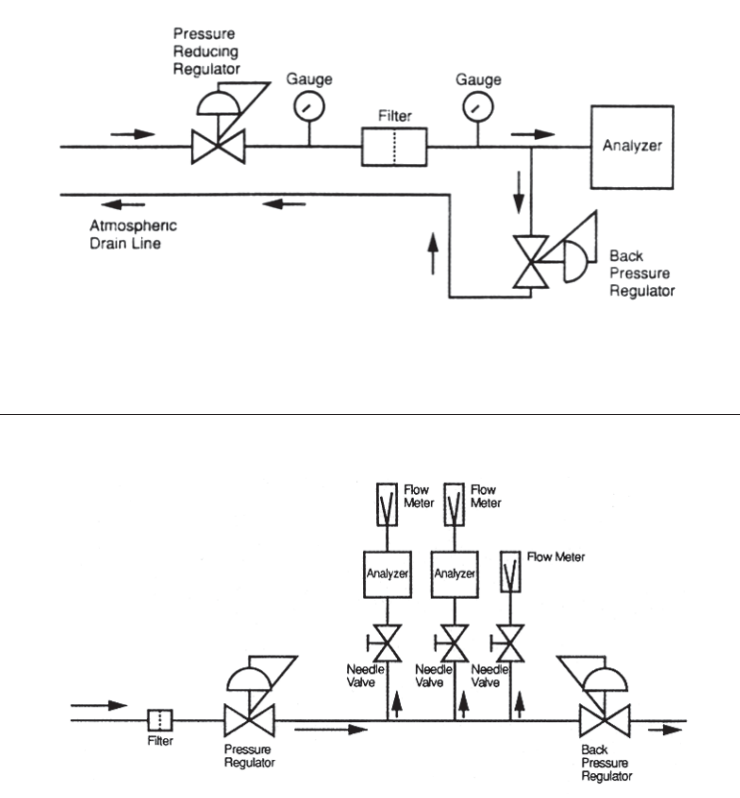

Some common installations for pressure reducing and back pressure regulators are shown below:

For additional downloads on bottle connector compatibility, physical properties of gases and guides on how to restrict a regulator, please click here to visit our resources centre.

Stock Listing

For readily available options, please view our Stock Listing and Enquiry Guide to help with selecting a suitable regulator, which can be downloaded by clicking on the image on the right.

We are constantly optimising our stock profiles to ensure that we have always have units readily available off-the-shelf in a variety of customised configurations.

Further Reading

If you are looking for more information or would like to explore our catalogue, visit our page on Pressure Regulators. Whether you are looking to control gas or liquids, need a custom design, or are searching for an off-the-shelf unit, we have the solution. With our extensive product range and leading technical know-how, specifying the right regulator for your process has never been easier. If you require any assistant sizing or selecting a suitable model, please get in touch with our expert team for guidance.