Paddle flow switches are used to monitor and control the flow of liquids or to protect additional equipment (eg. a pump) in many industrial processes. They typically consist of a housing with a pivoting paddle inside. When liquid flow moves the paddle inside, it triggers a switch mechanism, signaling the flow status via an alarm or PLC.

These switches are commonly used across industrial and commercial applications to ensure proper flow rates and identify issues like pump damage or insufficient liquid circulation.

Paddle flow switches are an excellent option for systems, due to their suitability for various liquids and pipe sizes. They are easily integrated into control systems for automated processes. They provide instant responses, as the paddle flow switch provides real-time feedback.

Paddle flow switches are a reliable, versatile and cost effective solution to your operational needs.

What are Paddle Flow Switches and How Do They Work?

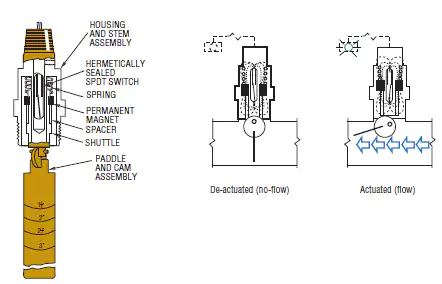

A paddle flow switch is a device used to monitor the flow of liquids inside pipes. They usually consist of a pivoting paddle inside an housing unit. When the liquids reaches a pre-determined level it will cause the paddle to pivot. This movement triggers a switch mechanism, either making or breaking an electrical contact. The change in the switch status signals the presence or absence of flow. This will result in an alarm out to alert the end user of this issue.

When liquid flows in either direction it deflects the paddle which, by cam action, displacing a permanent-magnet-equipped shuttle along the unit stem. The magnet actuates a hermetically sealed, magnetic reed switch within the stem to operate a remote alarm or indicator. See more details on our FS550 type paddle flow switch.

Types of Paddle Flow Switches

Magnetic Paddle Flow Switch

A flow switch with a paddle system operated by a permanent magnet embedded in it. The magnet is housed in the liquid flow route and is activated once the piston is displaced due to the change in pressure caused by the liquid flow. A simple and reliable method to detecting fluid movement in pipelines or systems. They are also used to prevent pump damage and system failures.

These types are most commonly used in:

- Pipelines

- Water Treatment Systems

- Cooling Circuits

Leaf Spring Paddle Flow Switch

A flow switch which uses a leaf spring mechanism to detect liquid flow. When the liquid flow moves the paddle, the leaf spring flexes and the motion is used to activate the switch. These switches are used to maintain the proper functioning applications and processes.

These types are most commonly used in:

- HVAC system

- Water Treatment Systems

- Chemical Processing

- Industrial Machinery

Paddle Wheel Flow Monitors

Additionally, we can also help with paddle wheel flow meters (rotorflow monitors) which can be equipped with visual indicators, switching signals or pulsed outputs for continuous monitoring.

Selection Criteria for Paddle Flow Switches

- Flow Rate Range - understand the flow range you need to measure. Flow switches will not indicate the actual flow rate just when it reaches a specific preset point. You will need to measure the average flow rate to determine the set point.

- Materials of Construction- ensure the body material of the switch is compatible with the fluid you require measuring. Also ensure the material can withhold the temperature of the fluid.

- Surrounding environment - ensure the flow switch can withstand environmental surroundings which can include the temperature exposure, pressure, density, flammable, corrosiveness, toxicity & viscosity.

- Switching mechanism - identify which paddle switch you require either magnetic or leaf spring based on the needs of the equipment.

Our knowledgeable technical support team at Boiswood can support you in selecting the correct flow switch to fulfil the needs of your application, ensuring efficiency & accuracy to support the high performance of your business.