Negative pressure rooms are critical spaces constructed to help battle infections. In hospital and other medical enviroments they are often referred to as isolation rooms, although they can also be found in various pharmaceutical and industrial settings for critical manufacturing processes.

Typically, having both visual and audible alarming capabilities is essential in these spaces to ensure the highest level of cleanliness standards. By utilsing negative pressure, you can help minimise and prevent the spread or transmission of infectious airbourne particles such as bacteria, viruses, fungi etc. COVID-19 has created heightened awareness of the need for negative pressure patient care spaces beyond the typical hospital isolation rooms.

How to Create a Negative Room Pressure?

In order to create a negative pressure room, you will need to manipulate the air flow through the HVAC system. This would normally be done by changing the differential pressure between the room (reference point) and the surrounding area (pressure pickup point).

Usually, the minimum required differential pressure for negative pressure spaces is -2.5 Pascals. Most hospitals will consider up to around -7.5 Pascals to accomodate for any inaccuracies within their existing HVAC systems. Ensuring a constant negative pressure room will stop any infectious or deadly particles from escaping that space. Aside from typical differential pressure monitoring, other measures such as dedicated ductwork, air filters and ACHs (air changes per hour) are good practices for creating negative pressure spaces.

How Can I Monitor the Room Pressure?

Our Lite visual room pressure indicator provides a simple, cost-effective, and accurate way to measure, display and monitor room differential pressure for spaces that currently require manual verification. For local staff managing an area, the Lite has an intuitive light ring that is green or red and an optional audible alarm providing clear indication of room pressure conditions. For facilities using the unit means the frequency of preventative maintenance walk-by inspections can be reduced because the Lite is monitoring the space.

The Lite is about the size of a standard light switch and is just as a simple to install. It fits in a single-gang US electrical box, international 86-box or international round back-box and is powered by 24VAC or 24VDC. The reference side pressure pickup is integral with the Lite faceplate. An analogue output provides the building management system with the pressure signal for any additional trending or alarming needed.

What are the Benefits for Pressure Monitoring?

The Lite visual differential pressure sensor has many features found only in larger, more complex room pressure monitors. Including a bright LED light ring that can be seen at an angle or down a hallway, a digital display of the pressure value that is always-on or momentary, an alarm delay for door entry, and POS or NEG room mode. A full list of advantages includes:

- Simple single room pressure indication for all pressurised spaces.

- Sleek and attractive single wall plate mountable in an international round back box.

- Multiple installation options include rotatable mounting position (vertical or horizontal) and quick mount/portable kits to assist with rapid critical care setup challenges.

- Simple to install in minutes keeping installation and maintenance time to an absolute minimum.

- Visual alarm via intuitive red/green LED light ring that is visible from a distance.

- Configurable audible alarm that can be heard up to 30ft away.

- Offset light pipe that can be seen at an angle or down a hallway.

- Digital display can be always-on or momentary.

- User-friendly and easy to configure using just 3 touch buttons.

- Analogue and voltage outputs as standard allow for connectivity to BMS system.

- Works with other environmental monitors and continuous cloud monitoring solutions.

- Available in white or black colour designs to suit any installation setting.

This easy and user-friendly room pressure indicator has Setra’s accuracy and reliability you know you can trust. For an overview of the product, please click here to watch our introductory video:

How Does it Work for Hospitals?

The Lite room pressure monitor is constantly being developed and upgraded based on customer feedback and market demands. We are pleased to announce that our room pressure indicator just got better, with the latest version of the model now with several new features and updates, increasing the functionality and usability for your specific needs:

Differential Pressure Monitor with Audible Alarm:

Based on increased customer demand, the Lite pressure monitor now has an option for a configurable audible alarm. The alarm can be heard up to 30ft way with typical background noise, and reports in 2 second intervals until acknowledged. To acknowledge the alarm, simply press the lens cover beneath the monitor screen. This feature can be toggled on/off via the push button menu.

Dual Alert Display for Inside & Outside Room Monitoring:

The dual alert option provides visual indication for both inside and outside the monitored space. Pairing the standard Lite with a matching pressure pickup port with visual light indicator provides an added level of safety for all space users and enhances the ability for the Lite to replace other existing monitors with little to no building modification. The dual alert functionality allows for simple, permanent monitoring of air flow where visual status is desired in both spaces.

Rotatable Display and Colour Options for Front Plate:

Two aesthetic options have been added for the Lite unit: colour and orientation. Depending on the needs of the space, the unit is now available in either black or white colour schemes, as well as mountable in either the portrait or landscape positions.

Applications for Positive & Negative Pressure Spaces

The Lite can replace outdated and unsophisticated technology such as ‘ball in tube’ or mechanical pressure gauges, offering more features for the price and reducing the need for manual inspections. Unlike the visual-only function of a ball in tube, our unit’s analogue or voltage outputs can be directly connected to a building management system (BMS) or some of our other environmental monitoring solutions. The Lite differential pressure monitor incorporates Setra's proven dead-ended capacitive transducer technology, offering superior sensing accuracy and longevity.

Some of the most common applications for our visual pressure indicators includes:

- Protective patient rooms for hospital and medical environments

- Isolation rooms (including ICUs and other critical spaces)

- Emergency ICU tents (ideal for quick mount and portable kits)

- Sterile processing and storage facilities (such as pharmaceutical manufacturing facilities)

- Medical testing rooms (such as Endoscopy and Bronchoscopy)

- Cleanrooms and High Purity facilities with high cleanliness requirements

- Any critical or reconfigured spaces (compliance to ASHRAE and USP 800 regulations)

Developed with Hospital, Medical, Pharmaceutical and Clinical environments in mind, we are here to help you with speedy production and unrivalled technical support. Centred around years of engineering, development and customer feedback, we have produced a complete solution to stage as an upgrade to traditional options such as mechanical DP gauges.

Capacitive Sensing Technology for Critical Environments

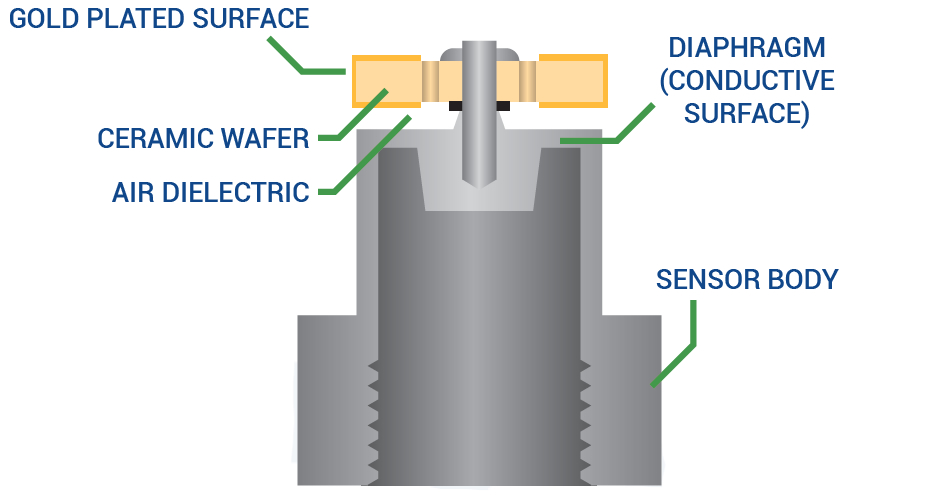

Since our partner, Setra, began manufacturing in 1967, capacitance has been and will continue to be the core technology for their differential pressure sensors. Each of the capacitive sensors that are manufactured employ two closely spaced parallel plates, one of which is fixed while the other is a flexible diaphragm which allows for motion when pressure is applied. This straightforward concept combined with innovative design and world class manufacturing has enabled us to become a leading supplier to the pressure sensor market.

These capacitive pressure transducers are expertly designed adaptations of a simple, durable and fundamentally stable device: the electrical capacitor. In a typical configuration, a compact housing contains two closely spaced, parallel, electrically isolated metallic surfaces, one of which is essentially a diaphragm capable of slight flexing under pressure. The diaphragm is constructed of a low-hysteresis material such as 17-4 PH SS or a proprietary compound of fused glass and ceramic.

These firmly secured surfaces (or plates) are mounted so that a slight mechanical flexing of the assembly, caused by a minute change in applied pressure, alters the gap between them (creating, in effect, a variable capacitor). The resulting change in capacitance is detected by a sensitive linear comparator circuit (employing proprietary custom designed ASICs), which amplifies and outputs a proportional, high-level signal. The advantages of using capacitance-based sensors includes:

- Quality and reliability you can depend on over a long-life span.

- Customistable platform products that can be made-to-suit any application.

- Class-leading overpressure capabilities to prevent unexpected damage.

- High accuracy ratings for critical environments.

- All sensor calibrations are traceable to NIST standards.

Other Ways for Measuring Differential Pressure

Our range of differential pressure sensors are known for their quality and reliability. Designed with premium capacitive sensing technology, our selection of Setra products offers single-range pressure sensors and multi-range (field selectable) pressure sensors. Capable of measuring both liquid and gases, we have the product to meet a breadth of HVAC applications and can be trusted in your most critical applications.

Differential pressure is important in the context of HVAC systems largely for efficiency. In a general building setting, maintaining differential pressure ensures enough airflow to condition the building, while not overworking the system - preventing unnecessary energy usage. Measuring the pressure differential across filters in HVAC ductwork, for example, also helps with predictive maintenance – reducing both short term and long term costs.

Our differential pressure sensors are considered best-in-class for a handful of reasons, including their accuracy, ranges, and stability. Our partner produces sensors with accuracy as high as +/- 0.02% Full Scale. The sensors reach measurement ranges as low as 0.05 inches of water column (approximately 0.0018 PSI) and their capacitive technology also allows extremely low impact from device age and environmental conditions when compared to competitive units.

Your Solution Partner

Our partner, Setra Systems, continues to design and deliver sensing devices for many diverse applications and industries — innovating solutions for HVAC & building automation, industrial OEM, test & measurement, and critical environments. Their ever-developing range of innovative products include differential pressure sensors, industrial pressure transducers, room pressure monitors & environmental control solutions, power meters, particle counters & air quality monitors.

For technical support on selecting the right pressure sensors for your application, get in touch with our experienced engineers here.