What is the DM555?

The DM555 is a single stage pressure reducing regulator that is manufactured by Mankenberg. Being a self-acting pressure reducer, the DM555 offers accurate control within your application and is easy to install and maintain.

The DM555 is a spring-loaded proportional control valve for universal application at small and medium rates. Made from SAE 316L grade stainless steel, the DM555 has excellent corrosion resistance giving it a long lifespan. The DM555 has a phenomenal cost-benefit ratio.

The valve can be used for toxic or dangerous media as it has a sealed adjusting screw and a sealed spring cap complete with leakage line connection.

Where Can You Find the DM555?

The DM555 can be found within applications in nearly all industries worldwide. This product is an industrial valve with optimised flow dynamics, making it the perfect valve for small and medium rate liquid and gases. The DM555 can be used in CO2 systems such as modulating panels and bottle filling plants.

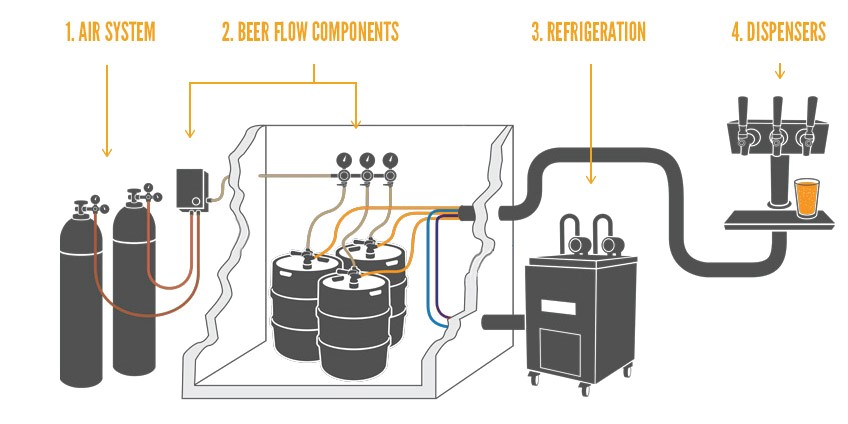

A small-scale common use of the DM555 is within a draft beer dispensing system in a bar or restaurant. In this application, the DM555 acts as a primary pressure regulator to ensure the correct amount of gas is pumped through the airlines. Saving space, the DM555 is also placed as the secondary regulator to make sure each individual keg is dispensed at the right pressure. The valve plays an important role within this application, making it easy to troubleshoot problems whilst dispensing the perfect brew.

Understanding It Further…

How does the DM555 work within applications? The force of the valve spring (set pressure) balances the outlet pressure across the control unit. The adjusting screw is used to set the pressure; when the outlet pressure rises above the pressure set, the valve cone reduces the volume of medium by moving towards the seat. As the outlet pressure drops, the valve control orifice increases; the valve opens once the pipeline is depressurised. Rotating the adjusting screw clockwise increases the outlet pressure.

Benefits and Special Features

The DM555 has a minimum closing pressure and a minimum control deviation in case the flow rate changes, this makes the valve easy to monitor and use. It has a small influence of changing inlet pressure and has a fail closed valve position. The valve also has the best flow characteristics and exact pressure regulation due to matching springs and control areas. This unit can be manufactured according to DIN or ANSI compliant standards.

Let’s Get Technical

| Connections (DN) | 15 - 50 |

| Connections (G) | 1/2 - 2 |

| Nominal Pressure (PN) | 40 |

| Inlet Pressure | Up to 40 BAR |

| Outlet Pressure | 0.5 - 16 BAR |

| KVS Value | 1.3 - 7.5 m³/h |

| Temperature | -35°C to +130°C (EPDM Seals) |

| Medium | Liquids and Gases |

What can Boiswood do for you?

As a leading partner with Mankenberg, we can offer you this fully customisable valve with a fast delivery time. Contact us today to speak to a representative for more details.