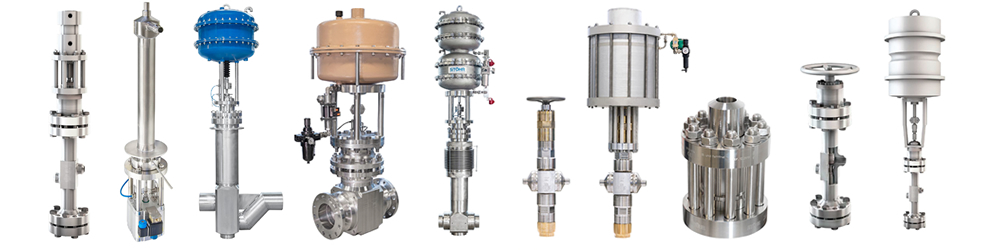

Our selection of cryogenic globe valves are available in manual, pneumatic and electric actuation types and can be used for on/off (shut off), flow regulating or control purposes. We can offer valves in straight-through or angle pattern configurations, from sizes DN2 to DN300, all available with a huge range of additional accessories including solenoid valves, limit switches, welding flanges, IP Positioners and more.

Our cryogenic globe valves can be made suitable for installation in any position, including in vacuum jacketed lines (VJ lines) or super insulated vacuum lines (SIVL). All valve bodies are machined from one singular piece of barstock 316L stainless steel (or specialty alloy) and comprise of a precision-engineering bellows seal for ultra-high leak integrity.

Cryogenic Shut Off Valves

A cryogenic globe valve – often referred to as an open/close valve or shut-off valve – controls the opening/closing of flow paths in pipes and is used to regulate the flow in gas and liquids installations. Globe valves can be operated manually using a hand wheel, by a motor, or by an external drive, which can be pneumatic, electric or magnetic. A globe valve is utilised to achieve either a full-flow or complete shut-off scenario, with the cone resting flat on the valve seat to interrupt the flow of media.

Our flagship Sticks cryogenic shut-off valves are designed to be a highly cost-effective solution for vacuum jacketed lines and cryogenic systems where on/off control is required. They are manufactured with high quality and precision engineered Stainless Steel Bellows for an extremely long operational life span and excellent leak tightness rating to atmosphere. The units are equipped as standard with a welding flange for vacuum insulation and can be installed with the stem up to 30° from vertical position.

The Sticks series valves are suitable for media temperatures down to -271°C, nominal diameters from DN15 to DN50, pressure ranges up to PN25 and are available as manual or pneumatic versions as standard. These cryogenic globe valves offer end users several market-leading features & benefits, including:

- Excellent price/performance ratio on standard valve configurations.

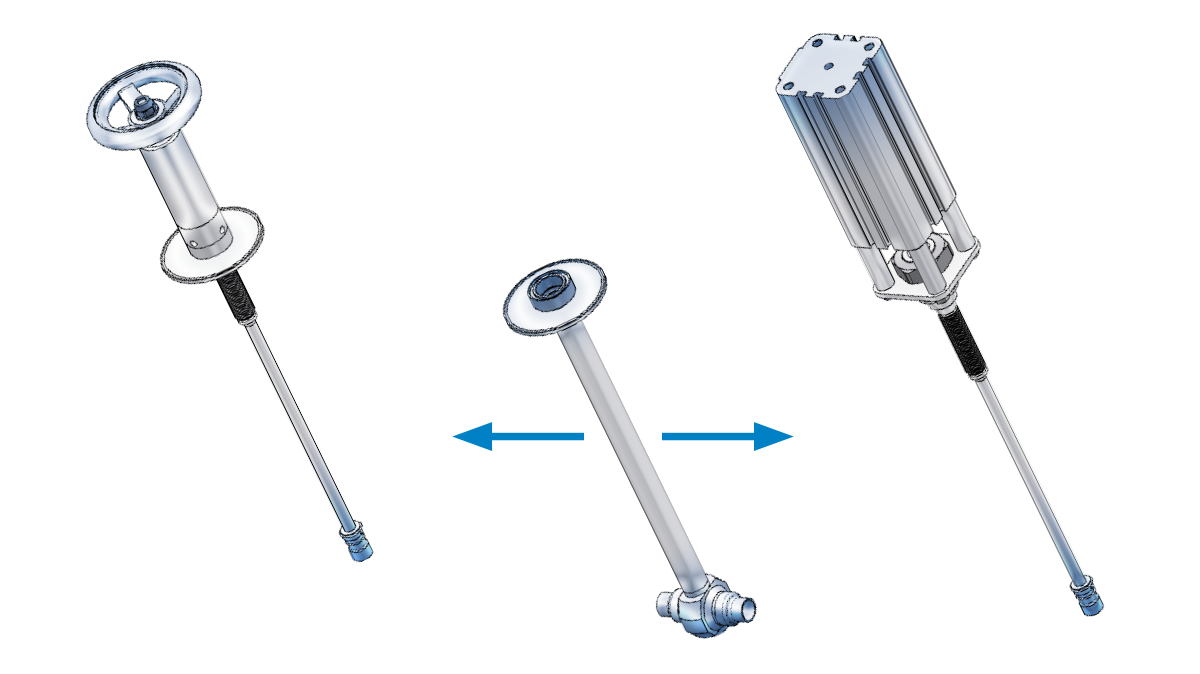

- Valve inserts (internals) are easily replaced or swapped in situ without needing to remove the valve body (see figure right). This allows the valve internals or actuation type to be converted at any point.

- Ready for installation into vacuum jacketed lines as standard.

- Very low heat load inputs thanks to the optimised bodies and internal design.

- Easy installation and space-saving design (small footprint) by using compact piston or diaphragm actuators.

Cryogenic Control Valves

A cryogenic control valve, or regulation valve, serves as an actuator in a control loop. As a throttle device, it enables the desired volume of flow to be set in a pipeline. For this purpose, the valve stem (spindle) is connected to the valve cone. This closes the valve seat ring by resting against the media pressure. When the spindle moves up, the flow opens and increases the flow rate depending on the profile of the control cone.

Control valves are typically controlled by an automated actuator. Manual control valves may be used, but these are less accurate. Most actuators are pneumatic, but electrical and solenoid actuators are also available. In addition to the pneumatic actuator, a control valve is usually equipped with a position controller (IP controller), and a limit switch may be used as backup.

Our ever-popular Univers cryogenic control valves are available in different series depending on your application requirements:

- The Univers 1200 cryogenic regulating valve is predominantly designed for gaseous media (such as Nitrogen, Helium, Hydrogen etc.).

- The Univers 1600 cryogenic control valve is mainly considered for extreme line size requirements (from DN2 up to DN300) and where an angle-pattern design can be utilised for optimised KVS values.

- The Univers 4200 cryogenic control valves is considered for high pressure applications up to PN250.

The Univers series valves are suitable for media temperatures down to -271°C, nominal diameters varying from DN2 up to DN300, pressure ranges varying from PN40 to PN250 and are available as manual, pneumatic, electric or solenoid actuated versions as standard. These cryogenic regulating valves are primarily utilised for their control (regulating) functionality, however they can also be offered as standard cryogenic on/off globe valves. Depending on the final model selected, these cryogenic valves can offer end users many advantages, including:

- Ideal solution for several harsh environmental conditions such as installation in seawater environments, desert conditions or very cold ambient temperatures.

- Angled body pattern for optimal flow conditions (KVS value).

- Low heat input and very high control accuracy.

- Various regulation cones and types available for different control characteristics.

- Highly customisable with many additional accessories and options available.

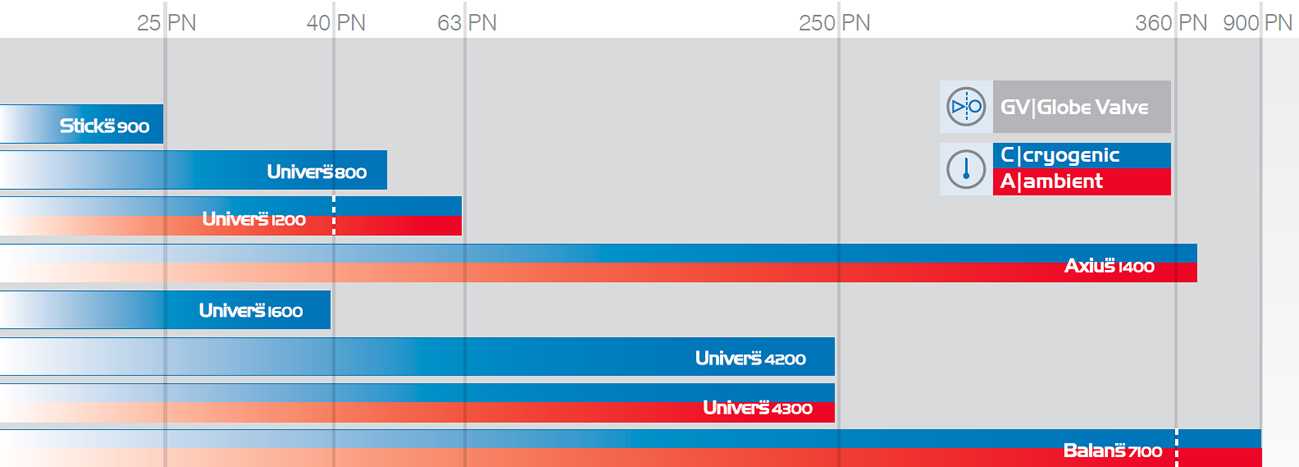

Comparison of our Cryo Valves

Our range of base cryogenic globe valve models includes:

- The Sticks 900 series which is the ideal solution where standard catalogue drawing numbers can be used with minimal modification. This series is a perfect starting point for any basic cryogenic valve requirements at an excellent price point.

- The Univers 800 series is available as a basic manual cryogenic valve with an optional integral check/non-return valve function.

- The Univers 1200 series is the ultimate solution where customisation is required. These valves are available in globe (on/off), control (regulating), non-return or filter designs and come with an endless list of additional accessories and modifications.

- The Frees 1200 series stands for free, efficient and secure. This cryogenic globe valve can be installed in any position (including horizontal or top-down) offering end users more possibility for pipe routing and utilising small spaces.

- The Axius 1400 series is a cryogenic globe valve with housing in an axial flow direction, featuring extremely fast opening and closing times, specifically designed for applications with very high pressures.

- The Univers 1600 series is an angled cryogenic valve (angle-pattern body shape) designed for extreme pipe sizes, high KV values and optimised control accuracy. This valve is especially popular for LHe processing due to the additional options available including Cu cold shield on the spindle extension, sliding heat contacts between the spindle and inside of the outer tube and non-metallic valve spindles.

- The Univers 4200 series is a high pressure globe or check valve for installation in vacuum jacketed pipework.

- The Balans 7100 series is a balanced lift valve designed for extreme conditions of up to 900 BAR, featuring low actuating forces and high leak tightness rating across the seat.

For an overview of the pressure & temperature ratings of these valve series, please see the below infographic:

Specifications for Cryogenic Valves

Since 1938, from standard valves to custom designed solutions - our partner, Stoehr Armaturen, has been unrivalled with expertise and technical know-how in manufacturing optimised solutions. Stoehr have always been well-known for their specialist designs, functional reliability and long operational lifespan.

For decades, Stoehr have been providing valves which have convinced customers through their quality and price, from small quantities of standard units to completely tailor-made solutions. Stoehr is renowned in the markets they serve for their technical expertise and comprehensive advisory service. We can work with you on a solution to meet the following specifications:

- Valve Types – Globe Valves, Shut-Off Valves and Control & Regulating Valves (All Bellows Sealed with additional 2nd seal to the environment), Check/Non-Return Valves, Filters, Blow-Off Valves and Valve Blocks.

- Medias – Gases and liquids including H2, He, N2, O2, CH4, NH3, CH3OH and more.

- Sizes – Nominal Diameters ranging from DN2 (<1/8”) to DN300 (12”).

- Temperatures – Cryogenic from 2K to 243K (-271°C to -30°C), Ambient from 243K to 323K (-30°C to +50°C) and Hot up to 676K (+400°C).

- Pressures – All pressure levels all the way up to ultra-high pressure of 1,000 BAR (100 mPa/15,000 PSI).

- Tightness – He leak tightness of 10E-8 mBAR l/sec to environment, He leak tightness of 10E-6 mBAR l/sec through the seat (subject to confirmation of valve type).

- Materials – All fully Stainless Steel materials (either 316L Stainless Steel or Special Alloys on request).

- Certifications – QM based on ISO 9001:2015, Pressure Vessel Regulation and AD2000-W2 H0, Explosion Proof for flammable media according to ATEX directive.

As a key partner of Stoehr’s high performance valves, we can also help with valve maintenance services, spare parts plans and technical training for end customers. Over the years we have become experts in the field of cryogenic valve technology.

Cryogenic Valve Applications

Our entire range of Stoehr valves is utilised across many industries including industrial & specialty gases, research & development, aerospace & defence and renewable energies. Our cryogenic valves can be used in the most cutting-edge applications such as vacuum jacketed lines (VJ lines) or super insulated vacuum lines (SIVL), cold boxes, cryocoolers & cryostats, science & high-tech testing facilities, cooling systems, research & development pilot projects, gas filling or transfer lines for cylinders, tanks or transportation and more.

Some example industries that we frequently work with include:

- Hydrogen & Clean Energies – hydrogen is currently seeing a renewed rapid growth both across Europe and worldwide. Hydrogen is ideally suited for energy transport and storage in existing infrastructures. Likewise, hydrogen will find use in many applications throughout industry, such as transportation and the energy sector as a carbon-free fuel. Green hydrogen is the effective energy supplier when it comes to decarbonising industrial processes and economic sectors where carbon reduction is both urgent and difficult to achieve. We are committed to making a positive impact on the environment and offers solutions for stationary and mobile hydrogen-based applications. Our valves and components meet requirements at all media temperatures, valve sizes and pressure ratings. Whether you are working on stationary applications for infrastructure, fueling stations, or distributed power systems, or perhaps mobile applications for aviation, marine, automotive, aeronautics, or rail, we are open to your challenge.

- Industrial Gases - many of our valves are used for the storage and handling of Nitrogen in gaseous or liquid form. Oxygen and, above all, hydrogen are being used more and more often, as the potential applications for customers in numerous industries continue to expand. We can help with sophisticated and durable valves for a range of demanding applications: valves for vacuum jacketing, for pressure levels of up to 1,000 BAR, to meet the safety standard for flammable gases, for difficult installation positions such as mobile trailers, and in extra-large nominal diameters of up to DN300.

- Aerospace – valve solutions from our partner have been used in aerospace activities since 1970, when they were first supplied for European space projects such as EUROPA, ARIANE and TEXUS. Our install base has increased with the reliability of our valves, and today, our valves are used in space activities around the world. As well as numerous applications in ground logistics, our valves have also been used in flight such as the TEXUS mission and components for satellites.

- Research & Development – cryo technology has increasingly found its way into wide scientific fields in recent years. In research applications, liquid helium (LHe) is often used as a media at temperatures just above absolute zero (-271 °C). Examples include the cooling of superconducting magnets, or use in cryostats, where the avoidance of heat input into the media for precise measurements is often the focus.

- Chemical – together with our partner, we have worked to develop and manufacture bespoke and standard valves for the chemical industry, as well as supporting all of the necessary tests and approvals associated with this market. Strict requirements placed on the media compatibility of the valve materials are typical for the chemical industry, often due to the toxic, corrosive or flammable properties. High demands are placed on the compatibility of the materials in use, especially steel type and sealing materials, and some material combinations – such as non-ferrous metals – must be excluded from use due to the environmental conditions of the plant. Specific QS tests may be required to ensure final acceptance and certification.

- Power Engineering – since the beginning of the 1960s, Stoehr Armaturen has developed and manufactured stainless steel valves for nuclear power plants, starting with the Dragon Project in the UK. Since then, our valves have been installed at numerous nuclear plants and sites in Germany and around the world. These valves are mostly equipped with solenoid magnetic drives and are used to control cooling processes in the outer cooling circuits of the reactor, and are therefore designed primarily for warm media temperatures.

- Naval, Marine & Defence – liquid natural gas (LNG) is widely used in civil shipping as well as for the ship's propulsion itself. In a recent project, large quantities of hydrogen are transported by ship. In military, the use of oxygen and hydrogen dominates – mainly to feed submarine fuel cells, or to ensure the oxygen supply in the cabin during a dive trip. For these and many other applications, we can offer both the optimum valve solution and extensive application knowledge for a vast range of operating conditions.

Cryogenic Valve Specialists

For information or advice on special design/custom cryogenic valves solutions, please get in touch with our experienced engineering team by clicking here. Our customisable selection of cryogenic valves can be made available with various actuators, including diaphragm, piston or electric, solenoid valves, position regulators, a selection of cone designs, purge ports, vacuum jacketing, sealing options, surface treatments, welding flanges, filter regulators, IP positioners, certificates and more.

Our selection of cryogenic components offers our customers a variety of options and configurations to meet almost any application. To explore our full range in more detail, please visit our category page here.