When it comes to pressure sensors, there is a tremendous number of choices available in today’s marketplace. All the different measuring technologies and principles that are promoted by manufacturers can make choosing the correct one a seemingly impossible task.

In this blog, we will specifically be showcasing some of our digital pressure sensors with advanced communication protocols, including possibilities of utilising IO-Link, USB and I2C.

IO Link Pressure Sensors

Our A-1200 pressure sensors have been designed for intuitive and flexible programming via an IO-Link connection. These state-of-the-art pressure sensors are an ideal solution for any modern applications whether you’re looking for simple pressure monitoring or electronic PNP/NPN switching for process control environments.

These pressure sensors ensure precise measurement results over a long-term period thanks to their integrated smart diagnostics functions that monitor the instrument status. Additionally, this digital pressure sensor can be configured remotely via the intelligent signal connectivity and conveniently adjusted at any time.

An intuitive 360° LED status ring provides a constant visual indication on the status of the sensor. Green indicates everything is good, Yellow indicates a critical state and Red indicates an error to enable end users with fast error detection and quick corrective action. This unit is designed to withstand rugged applications, with a robust sensor housing designed to resist shock loads of up to 1,000 G and media temperature ranging from -40°C to +125°C.

For more information, visit our product page or watch the product overview video below:

Why Use IO Link Communication Protocol?

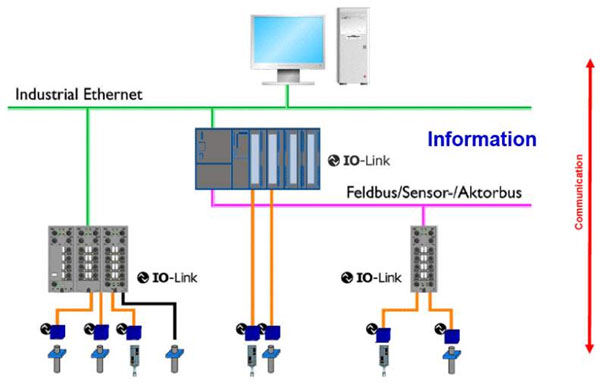

IO-Link is a digital communication interface in factory automation/machine building. Leading providers of automation technology have joined together to form the “IOLink consortium” and specified this modern interface. This interface can be used to exchange information on the already existing signal line all the way down to the field level, using a serial protocol.

The advantage is that, for example in the case of a pressure switch, bidirectional communication is possible via the already existing 3-wire connection. The following data can be exchanged using the standardized protocol:

- Measurement values - analogue or digital

- Configuration parameters - centrally from the control system to the sensor/actuator

- Diagnostic information - from the instrument to the control system

CANopen Pressure Sensors

Our P-30 and P-31 pressure sensors have been developed for precision measurements with a maximum measuring deviation as low as 0.05% of span. As a result of their active temperature compensation, these digital pressure transmitters have no additional temperature/thermal error in the range of -10°C to +60°C.

These pressure sensor models are available with CANopen output signals (as well as standard analogue and USB types). They offer end users a wide selection of electrical terminations, process connections and measuring ranges to choose from.

The high measuring and output rates of up to 1 kHz make the measured value available as quick as possible. The compact design makes tis pressure such ideal for mounting into test benches (such as 19” racks).

Digital vs Analogue Signals

In the case of CANopen communication protocols, most people have heard this term used as a digital signal possibility. As a general description, CANopen provides several communication objects that make it possible to implement the desired network behavior in an instrument. With these communication objects, instruments or sensors can offer the capability to communicate process data, display device-internal error states or influence and control the network behavior.

So why would you want to replace tried and tested analogue signals with digital ones? There are five areas in which we can identify advantages for using CANopen:

- Susceptibility to errors – higher susceptibility to errors with sensors using analogue signals due to the fact the signal is converted three times. First it’s concerted from analogue to digital (AD), then back from digital to analogue (DA) and finally digitalised again in the controller. Typically, in addition, the signal is even linearised which leads to further errors.

- Reliability – the advantage of a digital signal, in terms of reliability, is that it is precisely defined what kind of values are expected. The transmitted bits can be checked for plausibility by fixed fields, as well as by the message length. If, for example, a packet with 16 digits is expected but only 14 of them arrive, it is easy to identify an error in the transmission. This considerably reduces the susceptibility to errors due to external influences.

- Diagnostics – a detailed check of the system structure, for example which type of instrument is installed in which position, as well as a verification of the digital sensors is part of the standardised start-up process. Even during operation, a digital signal can be repeatedly verified (via. the heartbeat protocol or timeouts).

- Extension of the system – a major advantage of a digital system is the merging of signals. Up to 127 channels can be combined in one control system. If you start with fewer, a later expansion of the system architecture is no problem. In addition, the wiring is simple and the controllers become cheaper since 127 separate high-precision analogue channels are not necessary.

- Reusability and ease of maintenance – the entire scaling and calibration process is carried out on each digital sensor itself, for example if a 150 BAR pressure sensor is exchanged for a 250 BAR version, there is no problem. It is no longer necessary to change the control parameterisation as the sensors are only calibrated by the manufacturer.

USB Pressure Sensors

The HP-2 pressure sensor has primarily been designed for demanding high-pressure applications up to 15,000 BAR, making it one of the very few pressure measuring instruments in the world that can reliably measure pressures of this magnitude.

This unit (among other more standard models) is available with a USB output signal to allow measurement and adjustment of pressure ranges, zero point and span via the EasyCom 2011 software.

Thanks to its excellent load cycle stability, this pressure sensor has a particularly long service life, even with dynamic pressure profiles. Protection against cavitation and pressure spikes, specifically developed for highly dynamic pressure profiles, further extends the service life.

I2C Pressure Sensors

The MTF-1 pressure sensor module is designed for energy-saving operations. The digital I2C signal transmits data extremely efficiently thanks to the low basic energy consumption and fast switch-on times. The energy-efficient sleep mode further reduces energy consumption and makes the unit suitable for battery operation.

Thanks to the I2C digital protocol, parallel to the pressure signal, this unit provides a guideline value for the temperature in the sensor module, which can be used for condition monitoring of the instrument. With condition-based and preventative maintenance made possible by this, the service life can be significantly extended and repairs can be planned ahead.

This pressure sensor is a simple and flexible option for integrating pressure measurement into a wide variety of applications, ensuring precise delivery of data through digital processing.

What is an I2C Signal?

I2C was designed to communicate over short distances between printed circuit boards and is a simple, 8-bit serial data bus. In the meantime, it is not only PCB-mountable pressure sensors that use the I2C signal for data transfer, but also pressure sensors remote from customer electronics.

Remote sensors usually have the advantage of being less sensitive to contaminated or aggressive media and being able to measure directly at the process. In the case of sensors mounted directly on the circuit board, the sensor element is, in many cases, exposed directly to the medium. With remote sensors, steel or ceramic generally serve as the wetted surface.

The I2C bus, alongside the two supply lines, requires only two further lines:

- SCL (serial clock line)

- SDA (serial data line)

UART and SPI Pressure Sensors

The TI-1 pressure sensor module is manufactured on state-of-the-art production equipment, enabling the greatest flexibility in OEM solutions and fast delivery times. A wide range of designs in process connections, electrical connections and case specifications are already available.

As output signals, these sensors are available with modern digital communication signals such as UART and SPI (as well as I2C and other standard analogue/voltage outputs). Via the digital interface, the sensor unit can provide information such as the sensor temperature reading.

This sensor model serves as the core for a broad variety of applications, such as data loggers, pressure controllers or as components in hand-held measuring instruments.

How to Select a Pressure Sensor

Pressure Sensors (or pressure transducers) are components that work by converting an actual pressure value into an electrical signal. Pressure sensors are available with a variation of different sensing elements and respond to the force applied to this element by gas or liquid pressure. The force applied to the element is then measured and converted into an electrical output signal, allowing it to be monitored by PLCs, processors and other computers.

For more information on the types of pressure sensors available on the market, how the different sensing technologies can work and specifications needed to correctly select one, click here to visit our other blog post.

Pressure Sensors with Digital Output

Our enormous selection of pressure sensors features an extensive range of options, technologies and configurations to meet the most demanding applications. To explore our full range of pressure sensing solutions, please visit our category page here.

For technical support on selecting the right sensor for your application, get in touch with our experienced engineers here.

Looking for a quick delivery? To view our selection of pressure sensors in-stock and readily available for next-day delivery, click here to see our intuitive part number configuration.